Gold Plating Frequently Asked Questions

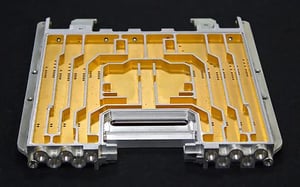

Gold is commonly thought of as a luxurious, expensive, and aesthetically pleasing metal. To the average person, gold is traditionally seen solely for its decorative value. While it makes for a great gift, gold is also an incredibly versatile and unique metal. These qualities make gold a highly sought after metal finish in advanced manufacturing- particularly in the Medical Device, Defense, Aerospace, Semiconductors, Telecommunications and Electrical industries.

When you provide gold plating in Massachusetts for a variety of industries like AOTCO, you receive lots of questions about the gold plating process. We know that investing in metal finishing can be a challenging decision to make, and though we cannot predict every question you might have, here are some of the most common questions we have the answers to.

What is Gold Plating?

Also known as gold electroplating, gold plating is the process of applying a thin coating of gold onto the surface of a different metal. This occurs through a procedure called electrodeposition. The object-to-be-plated is placed in a liquid electrolyte solution. The solution is a metal salt mix that contains ions of the metal that are desired for plating (in this case gold) and other chemicals.

While in the solution, an electrical current is passed through causing a reaction that binds the gold ions to the surface of the object. This results in a thin layer of gold completely encasing the original metal, giving it an array of new qualities and benefits.

Why Gold Plating?

As mentioned, gold has a wide range of desirable qualities that are great for a variety of different industries. From aerospace to defense engineering, gold plating has a spectrum of uses. Some of those uses are listed below:

Gold Plating Strength & Malleability

Gold is a virtually indestructible metal that is simultaneously highly moldable. A unique combination of wear resistance and malleability; this makes it great for mechanical parts that experience high use or require increased flexibility. Parts like turbine blades, switches, and relays all benefit from the strength and malleability of gold.

Gold Plating Conductivity

A lesser-known quality of gold is that it is a naturally good conductor, with its ability only being surpassed by copper and silver. Gold plating is often used in instances in industries that utilize electronic components or parts, since it is greatly effective at carrying electrical signals.

Gold is also non-magnetic, meaning that it won’t interfere or obstruct radio signals, making it a great plating choice for electrical radio components such as wires and antennae. On top of this, gold is a noble metal. This means that it is highly resistant to corrosion and tarnish, unlike silver and copper.

The corrosion resistant properties of gold allow for increased longevity and functionality of whatever electronic parts it is encasing. It is commonly used on parts like semiconductors, switches, circuit boards, and other similar items.

Gold Thermal Resistance

Gold has one of the highest melting points of all the metals on the periodic table. By not melting until it reaches 1,948°F (1,064°C), gold is incredibly heat resistant. Gold plating is often used on parts that need to withstand high temperatures for an extended period.

Gold is also highly reflective, which causes it to absorb significantly less solar radiation than its metal peers. This reflectivity is great for parts in the aerospace and defense industries that may be subjected to long periods of sunlight or radiation.

What metals are usually plated with gold?

Gold can be applied on nearly any metal, but it is commonly plated on copper, brass, aluminum, and nickel. Often, nickel will be used underneath a gold plating to act as an extra corrosion resistant material. The combination of both nickel and gold greatly increases the durability of the metal. The nickel also acts as a diffusion barrier and can help prevent the distribution of other metals on the gold's surface.

What class and type of gold do you offer?

We provide gold plating for all applications and specialize in the Aerospace, Telecommunication, Optical, Medical, and Electronics industries. AOTCO offers both hard and soft gold plating with Type I, II, and III, as well as Grade A, C, and D.

What’s the Difference Between Hard Gold and Soft Gold?

There are many differences between hard and soft gold plating, but the largest one is their purity. Hard gold is alloyed with other metals to enhance the strength of the gold. Soft gold is unaltered, and essentially pure gold.

Hard gold is often used when a stronger base material is required, or if there is any bonding or smoldering that needs to occur. Soft gold, since it is more pure than hard gold, is less corrosive. The high purity of soft gold also gives it an aesthetically pleasing advantage over its harder counterpart.

What Gold Specs do you Follow?

When working with highly specialized industries like defense or aerospace engineering, companies will often require a set of procedural standards to be followed. These specs allow us to have a better understanding of what is expected of us from our clients. Some of gold plating specs that we are compliant with include:

MIL-DTL-45204

AOTCO complies with the MIL-DTL-45204 gold plating spec. This NADCAP approved spec provides us with the requirements we need to meet to complete gold plating orders for the U.S military and its constituents. This spec determines the typing of the gold based off its purity. Type I has 99.7 percent gold content, Type II has 99.0 percent, and Type III has 99.9 percent.

ASM 2422

A standard commonly used within the aerospace industry, ASM 2422 is a spec that abides by electrical engineering standards for gold electroplating. The spec states that the gold being used must have a 99.0 percent gold purity minimum as well as a thickness of no less than 0.00005 inch.

With extensive experience plating gold in the Medical Device, Defense, Aerospace, Semiconductors and Electrical industries (to name a few), AOTCO’s professionals would love to provide your gold metal finishing needs to your exact requirements and specifications.

Please contact us for more information about our gold plating at (888) 275-0880.